Lion EV E Rickshaw Rear Drum Brake Plate

To manufacture the part with 2 mm thickness, we use a two-die process. The first die performs blanking, flanging, and forming operations in a single stroke, allowing for efficient shaping of the initial profile. The second die is a punching tool used to trim and define the final shape of the component with precision.

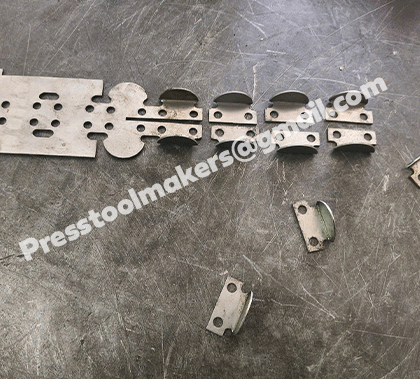

Aluminum Door Lock Clamp – Progressive Tooling for Mass Production

We have successfully developed and manufactured a 2-piece progressive tool in-house for the mass production of Aluminum Door Lock Clamps. The tooling system is integrated with an automatic feeder and decoiler, ensuring high efficiency and precision during the manufacturing process.

Reshoring Metal Stampings Package

A Mechanical Power Transmissions producer was getting Metal Stamped products from overseas. This caused many issues for them including very lengthy lead times, raw materials that did not meet specs, and ANSI Standard Dimensional Issues. Die Makers Mfg worked with the customer and rebuilt 60+ Compound and Progressive tools to produce high quality parts in the USA while holding +/- .0003 Tolerances.

Reshoring Metal Stampings Package

A Mechanical Power Transmissions producer was getting Metal Stamped products from overseas. This caused many issues for them including very lengthy lead times, raw materials that did not meet specs, and ANSI Standard Dimensional Issues. Die Makers Mfg worked with the customer and rebuilt 60+ Compound and Progressive tools to produce high quality parts in the USA while holding +/- .0003 Tolerances.

Reshoring Metal Stampings Package

A Mechanical Power Transmissions producer was getting Metal Stamped products from overseas. This caused many issues for them including very lengthy lead times, raw materials that did not meet specs, and ANSI Standard Dimensional Issues. Die Makers Mfg worked with the customer and rebuilt 60+ Compound and Progressive tools to produce high quality parts in the USA while holding +/- .0003 Tolerances.